English

English  Esperanto

Esperanto Afrikaans

Afrikaans Català

Català שפה עברית

שפה עברית Cymraeg

Cymraeg Galego

Galego Latviešu

Latviešu icelandic

icelandic ייִדיש

ייִדיש беларускі

беларускі Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ភាសាខ្មែរ

ភាសាខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Тоҷикӣ

Тоҷикӣ O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra Հայերեն

Հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba অসমীয়া

অসমীয়া ଓଡିଆ

ଓଡିଆ Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

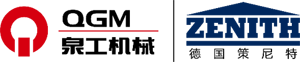

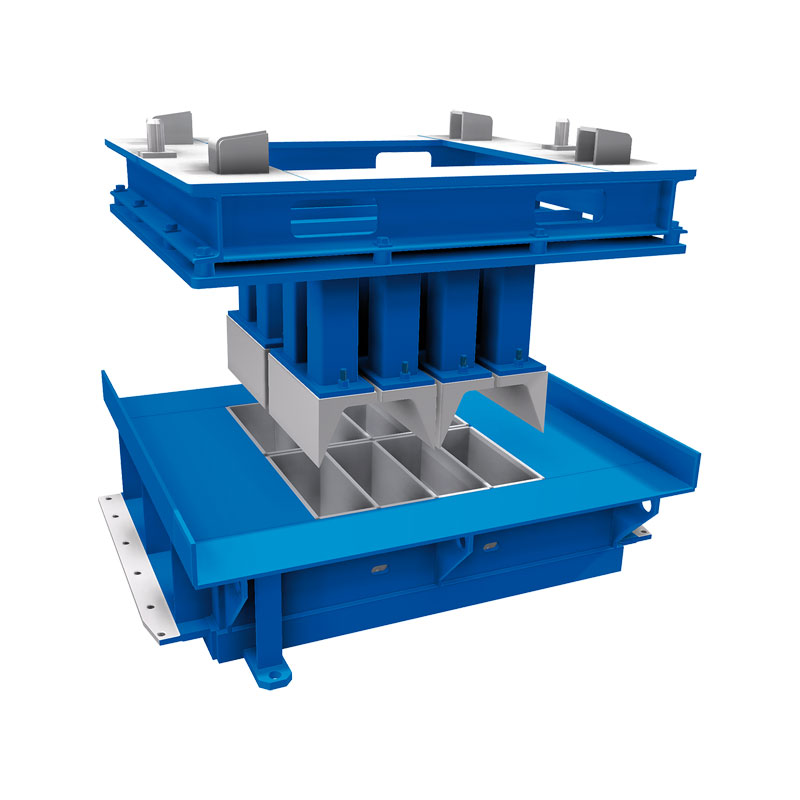

Paver Mold

Auina atu Su'esu'ega

I le avea ai ma kamupani gaosi oloa, matou te fia tuʻuina atu ia te oe Paver Mould. QGM paver mold e faʻaaogaina le uʻamea maualalo carbon alloy maualuga malosi carburizing sila ma tuʻufaʻatasia saʻo uaea tipi tekinolosi maualuga-saʻo CNC gaosiga tekinolosi ma 3D suʻesuʻega tekinolosi e tuʻuina atu ai tagata faʻatau ma faʻasologa masani. O nei tekinolosi e mafai ona mamanuina se vaniety o contours ma geometric shapes.O lona kiliaina o le 0.3-0.4mm, faatasi ai ma tulimanu tuusaʻo saʻo ma: mooth sidewalls. Pavers gaosia e QGM e faigofie-demoulding, maualuga saʻo, leai ni pupuni faataamilo. E mafai ona iloa e limu mamanu freesurface faafuainumera ma ipu mamafa fesuiai mamanu.

Ina ia mautinoa le umi o le limu, QGM paver limu faʻaaogaina carbunizing treatment., faʻamaʻaina framies ma ipu mamafa 60-63HRC, ma le loloto faʻamaʻaʻaina mirnimuim o 1.2m. E tusa ai ma talosaga a tagata faatau, e mafai ona mamanuina le limu ma gaosia e ala i le uelo po'o le lokaina filo modular.

Matou te ofoina atu le maualuga o Paver Molds mo ituaiga uma o masini ma mea faigaluega i le mamanu nei:

A) MOULED DESIGN AGA ITIITI

E mafai ona fai le mafiafia vaapiapi

Fa'aoga sili ona lelei o le limu

Fa'amaufa'ailoga fa'ailoga fa'amau fa'atatau ile masini ole 0,2-0,5 mm

E mafai ona fa'aogaina puipui o le itu fa'afeagai

Leai ni tootoo uu e mana'omia

Fuafuaga masani mo masini gaosi multilayer

Fa'ailoga pepa fa'asolo

E ala i le digitalization saoloto mamanu luga realizable

Fa'ailoga fa'ailoga fa'ailoga fa'a vevela e mafai

B) MOULD DESIGN MILLED

Fa'atatau i ta'oto uma ma geometries

Fa'apalepale i totonu o le pusa limu i lalo +/-0.3 mm

Fa'amaufa'ailoga fa'ailoga fa'amau fa'atatau ile masini ole 0,2-0,5 mm

Tu'u sa'o, fa'aitu ma lamolemole puipui itu

Faigofie le demoulding

maualuga le sao atoatoa o le fetaui

Avanoa umia i mamanu uma e mafai ona mafai

Fa'ailoga pepa fa'asolo

E ala i le digitalization saoloto mamanu luga realizable

Fa'ailoga fa'ailoga fa'ailoga fa'a vevela e mafai

Fa'aofu le puipuiga mo fa'amea uma e pei ona ta'ua i lalo:

A) CARBURISING(62-68 HRC)

Pusa limu ma fa'ailoga fa'ailoga ua malo (62-68 HRC)

Ma'a'a ulu min. 1,2 mm

B) FA'A'U'U (62-68 HRC)

Pusa limu ma fa'ailoga fa'ailoga seevae fa'amamafa (62-68 HRC)

Ma'a'a ulu min. 0,4 mm

E seasea so'o se fa'alavelave fa'alotoifale fa'atusaina i limu e togafitia i le carburizing

Fautuaina mo mafiafia laiti upega

E sili atu le sa'o o le kosi i luga o limu ua togafitia e le carburizing

I le mulimuli ai i manaʻoga mai tagata faʻatau, e mafai ona mamanuina a tatou mamanu ma gaosia i le faʻaogaina poʻo le faʻaogaina o filo faʻapipiʻi auala loka.